Reuse

Heerema’s Steel Marketplace

What is reuse?

Wind turbines and components can be used again for the same function, which has been legally defined as “any operation by which products or components that are not waste are used again for the same purpose for which they were conceived”.

Many turbines are reused in entirety carefully decommissioned and rebuild in a new location. Wind turbines can also be reused for parts.

Before reuse, turbines and parts are inspected, for example to assess remaining useful life, and whether any repairs and replacements are necessary. They may be stored for some time, before being used again in a wind farm.

Durable designs and good maintenance and repair throughout the lifecycle of a wind turbine can enhance reuse.

Reuse offers additional carbon savings by avoiding emissions from material sourcing and component manufacturing. Reused parts can generally be supplied faster and more affordably than new parts. Manufacturing of certain parts may have seized, leaving reuse as the only option to access the parts. Reuse also offers new business and employment opportunities in the wind industry.

While reuse is often considered for wind turbines, it can also apply to the supply chain and supporting services.

Circular strategy

Reuse

Heerema focuses on retaining resource value through reuse, sustainable procurement, and end of life and waste management.

Environmental Impact

By reusing steel and other materials, Heerema significantly reduces waste, lowers carbon emissions, and conserves raw materials, promoting sustainability in offshore projects.

Societal impact

Heerema’s circular practices create awareness and set industry benchmarks, encouraging responsible resource management and supporting sustainable development goals.

Business impact

The steel marketplace of Heerema reduces procurement costs, enhances project efficiency, and supports compliance with sustainability directives, driving long-term business value.

Material/component

The strategy addresses steel structures and components, enabling their reuse across multiple offshore projects and minimizing the need for new resources.

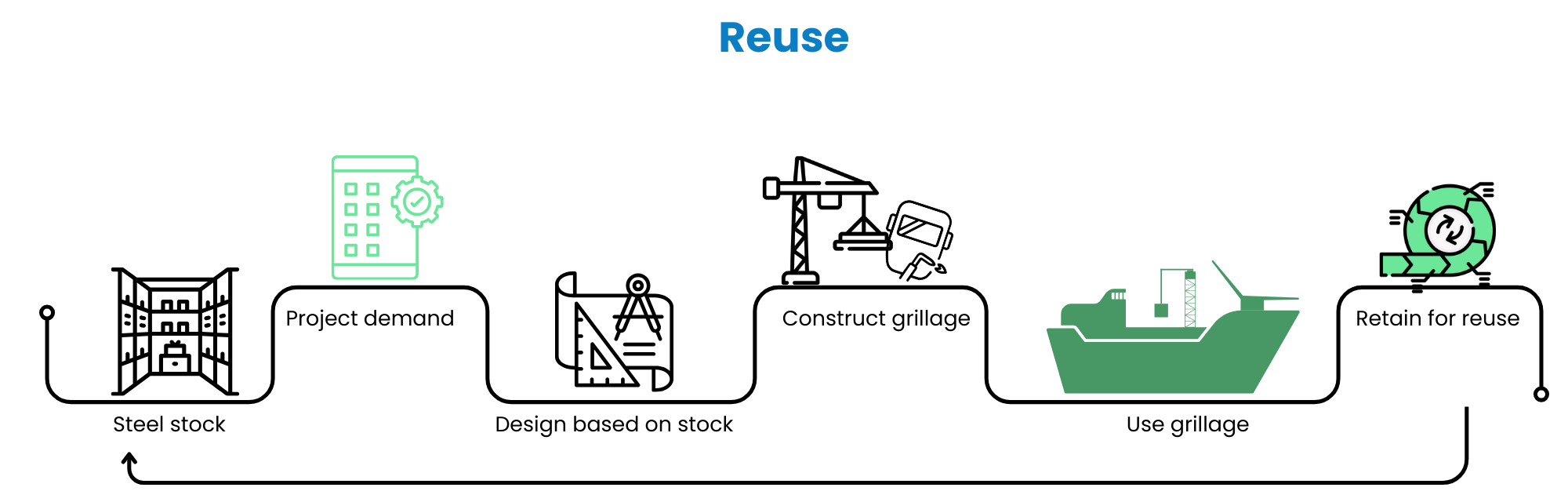

Steel Reuse at Heerema Marine Contractors

Heerema Marine Contractors take a sustainable approach by re-using steel from previous offshore installation and decommissioning projects. For years, they have leveraged an internal material hub called the Steel Marketplace. Customers can browse through pre-used steel components, giving them a new lifecycle in projects. Integrating this practice reduces waste and supports sustainability goals by reducing the carbon footprint as emissions are reduced which are otherwise associated with the manufacturing of steel.

Advancing Circularity with Established Practices

Heerema sets specific reuse targets for its projects. Their internal Steel Marketplace enables project teams to achieve these goals by providing engineers access to valuable resources. Every piece of pre-used steel is assessed for suitability, ensuring it meets safety and quality standards before being reintegrated into new offshore projects. This proactive re-use of resources underscores their commitment to setting a circular standard in the industry. Heerema defined organizational reuse targets and end-of-life strategies to eventually close, narrow and slow the loop. The challenge remains in deciding what to retain and what to pass on.

Collaborating for Industry Impact

When reuse in-house is not feasible, alternatives to preserve material potential are sought through partnerships to extend the lifecycle of steel parts. Heerema’s steel reuse strategy can unlock new collaborative applications for pre-used materials, including in wind projects. Heerema welcomes partners and fresh ideas to help drive circular practices and advance circular resource management together.

Infographic

Circular Heerema

Heerema’s circular strategy goes beyond the reuse of steel, focusing on retaining the value of all materials while gradually expanding its scope. The approach addresses the full lifecycle of materials, starting with sustainable procurement, critically evaluating the necessity of products and resources. At the end of the cycle, they prioritize responsible waste stream management, implementing initiatives such as waste analysis, segregation strategies to maximize value, copper cable stripping, and recycling.

About Heerema Marine Contractors

Heerema Marine Contractors is a global leader in offshore solutions, committed to embedding circular economy principles into our core practices. With over 2,500 employees world-wide, we are dedicated to reducing the environmental impact of energy infrastructure projects. Through our Steel Marketplace and partnerships with other industry players, Heerema is at the forefront of the industry’s shift toward a more circular and sustainable future.

Other circular strategies

See here the other Circular Strategies, which already provide a frontrunning showcase or are still available for new industry partners!

Repurpose

Repurpose Refurbish

Refurbish Waste prevention

Waste prevention Reuse

Reuse Dematerialise

Dematerialise Remine

Remine