Dematerialise

Going TP-less with Skybox© to reduce material use

What is dematerialising?

Dematerialisation fits within circular economy strategies focused on minimising resource use. It is one of the most effective approaches to reduce costs and environmental impacts, and forms an essential part of building sustainable circular economies together.

The processing of materials (e.g. metals, concrete, glass) and the manufacturing of components costs energy. The relatively modest environmental impacts of wind energy are largely caused by the material sourcing and component manufacturing. Creating more value with less materials is therefore vital for sustainability.

This can be achieved through, for example, shape optimisations that make components stronger with less materials. Research, development and innovation is on-going into more efficient alternative materials. Moreover, material use can be minimised with more durable designs to reduce the material intensity for every year that a component is in use.

Dr. Anne Velenturf, University of Leeds.

Circular Strategy

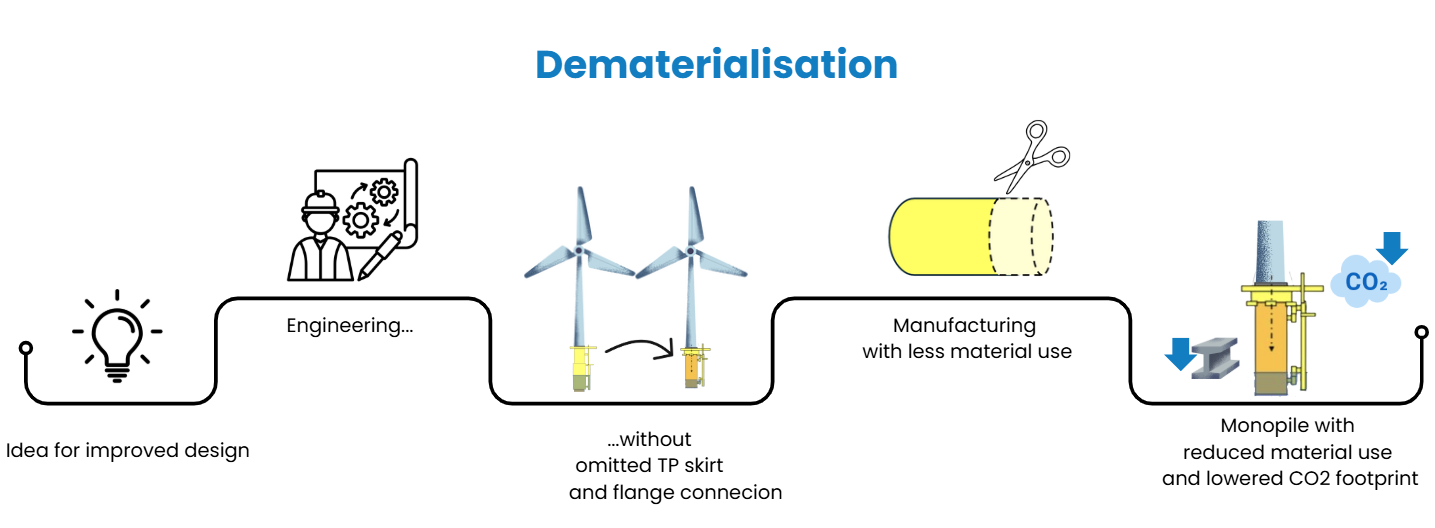

Dematerialisation

The material or component that is involved during the dematerialisation is steel.

Environmental Impact

By removing the transition piece (TP) interface, we reduce 5% material. Also, the production, installation and maintenance phases will be less extensive, reducing GHG.

Societal impact

Reducing virgin material results in less impact from mining. This design improves public perspectives on wind energy, often negatively framed due to heavy material use.

Business impact

Making a TP-less monopile (MP) is less complex due to the exclusion of the complex TP-MP connection. We can produce more monopiles if we go TP-less, increasing our capacity output to the market.

Partner

For following the dematerialisation strategy, Smulders N.V. can manufacture the Skybox©.

Dematerialisation MP/TP versus TP-Less

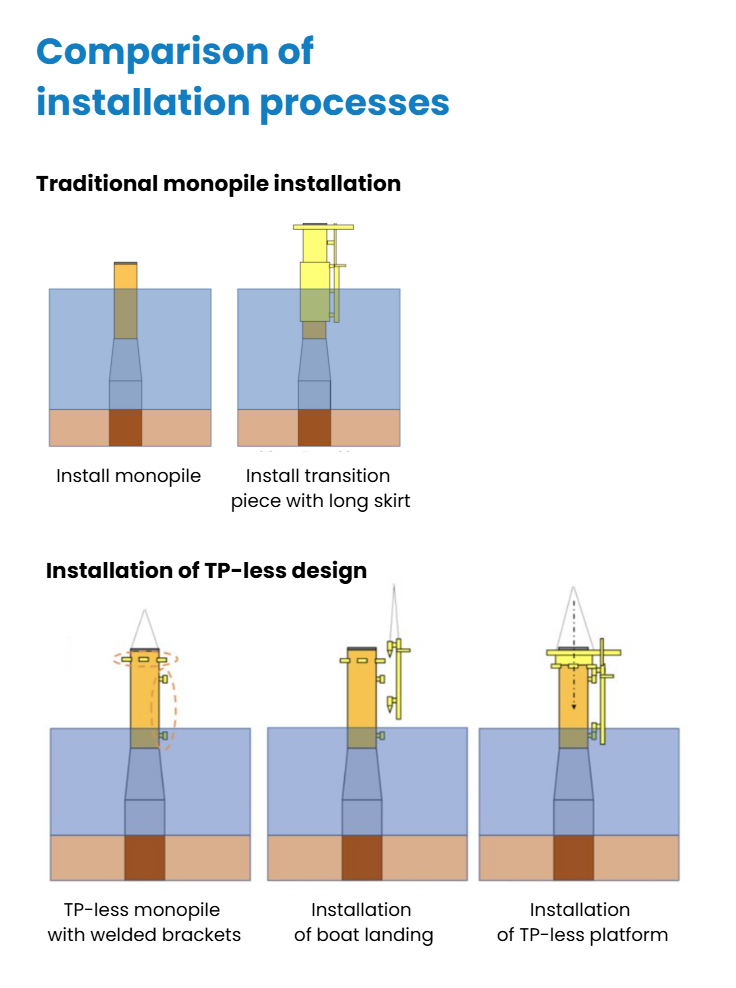

Transition Piece-less (TP-less) monopile design integrates the wind turbine tower directly onto the monopile, eliminating the need for a transition piece. Sif’s extensive manufacturing experience with proven optimisation capabilities in the manufacturing of TP-less monopile design offers clients substantial economic and materials savings. This can be achieved by reducing both the steel usage and the overall weight of the foundation structure in comparison to conventional monopile designs. In addition, the omission of bolted flange connections also allows for a uniform coating layer, which extends the monopile coating’s lifetime.

Looking beyond the production and operational phases, the less complex and more uniform structure of the TP-less design is easier and more cost-effective to decommission and recycle, supporting the business case for End-of-Life solutions.

Overall, the use of a TP-less monopile design contributes to reduction in usage of (critical) raw materials and energy while improving efficiency during every phase of the wind turbine lifecycle; from manufacturing, offshore installation, O&M to decommissioning and recycling. This makes it an impactful solution for the circularity of offshore wind farms.

Sif estimates 5 to 10% steel reduction when going for a TP-less Monopile. This could result in 200 metric tonne steel reduction per foundation.

Impact of going TP-less?

When changing the design, one needs to assess the impact on the value chain to understand if the circular strategy is adding value to the total lifetime of the product. Sif has analysed the following in close collaboration with its industry partners:

- Pro: Design Benefits: Transitioning to TP-less configurations can streamline the design processes of primary and secondary steel components. This separation allows for quicker finalization of primary steel designs and accommodates the more complex secondary design requirements.

- Pro: Operational Efficiency: TP-less designs simplify the installation process by eliminating the need for the bolted connections required in TP configurations. This not only reduces installation times but also cuts down on long-term maintenance and inspection requirements, offering substantial economic advantages.

- Pro: Economic Impact: The analysis suggests significant capital expenditure (CapEx) savings in the range of €250k to €300k per foundation, with further operational expense (OpEx) reductions due to less frequent bolt inspections and maintenance. The overall economic benefit is supported by the growing availability of suitable installation vessels, which are crucial for accommodating the heavier and longer TP-less monopiles.

- Con: When going TP-less, approximately 10 metres of tubular steel is added on to the MP, making the MP 125–150 tonnes heavier. Most fabricators have no issue with this; however, installing these higher MP weights and lengths might require the latest generation of installation vessels to be available. However, from a macro view, it seems that the fleet of installation vessels capable of installing TP-less monopiles is growing rapidly and is keeping up with the growing demand over time.

Next to the above, there is an obvious con, by removing the TP you will also remove the secondary steel platform, crane, cable platform etc. Sif has analysed this con, and found the solution in the form of the offshore skybox

Skybox solutions

Sif’s Skybox is an innovative main access platform for TP-less monopiles in offshore wind farms. The patented Skybox can be installed in a single lift making use of a slip joint connection, evading the need for welding brackets onto the monopile. This omission of brackets in the Skybox design enables Sif to produce the monopile in series without shipping the parts to a secondary steel outfitter. At the same time, the Skybox concept requires fewer inspections and less maintenance for coating issues than bracket-based constructions. Decommissioning of the Skybox platform is also straightforward: it can be easily lifted off the conic structure of the TP-less monopile. Recycling of secondary steel will benefit from this simple decommissioning concept.

Sif developed Skybox to enhance the efficiency of monopile installation and decommissioning, while material consumption to produce the Skybox is also lower compared to traditional designs. For clients, implementing Skybox in their designs leads to optimalisations in steel usage and efficiency. This reduces the footprint throughout the total life cycle of projects, with an additional benefit of cost savings for the total foundation costs for TP-less monopiles.

Infographic

Summariszing

Sif actively advocates Supply Chain Cooperation, being part of an ecosystem that supports and enhances circularity within the offshore wind industry. Our policy on product innovation is targeted to support the further deployment of monopile technology, including its footprint and circular impacts. With this in mind we support numerous start-ups and research projects while we execute several internal innovative projects such as skybox.

Using the TP-less Monopile with skybox reduces the total material use with approx. 5%. After assessing the impact in the industry, we concluded that it will also improve the design, production, installation and operation phase. This is a perfect example of how circularity can also improve the gains for the complete value chain.

If you want to learn more about Skybox and TP-less Monopile design, please reach out to our Programme Manager Stefan Erents.

Sif Netherlands

Sif Netherlands BV has been around since 1948 and has built up an excellent reputation over the years. Starting out as a manufacturer of large and thick tubular steel structures only, we have since evolved to supply complete monopile foundation solutions to the offshore wind industry. With two production sites in the Netherlands in Roermond and at Maasvlakte 2 in Rotterdam. For over 75 years now, we have been innovating and building the foundations for a sustainable tomorrow for future generations. Sif is constantly developing the products and services that enable us to supply exactly what the market needs. Wind farm developers can turn to us for foundation design, corrosion protection and logistical services such as warehousing and transloading. With our advanced machinery and production processes, we are capable of manufacturing 200 XXXL monopiles every year. Each one of these steel tubes weighs 2,500 tonnes and has a diameter of 11 metres and a length of 100 metres. The result is an annual production capacity of 400,000 tonnes, which equals an offshore wind capacity of 2,400 MW every year.

Other circular strategies

See here the other Circular Strategies, which already provide a frontrunning showcase or are still available for new industry partners!

Repurpose

Repurpose Refurbish

Refurbish Waste prevention

Waste prevention Reuse

Reuse Dematerialise

Dematerialise Remine

Remine