Waste prevention

Zero Waste Blade 2030

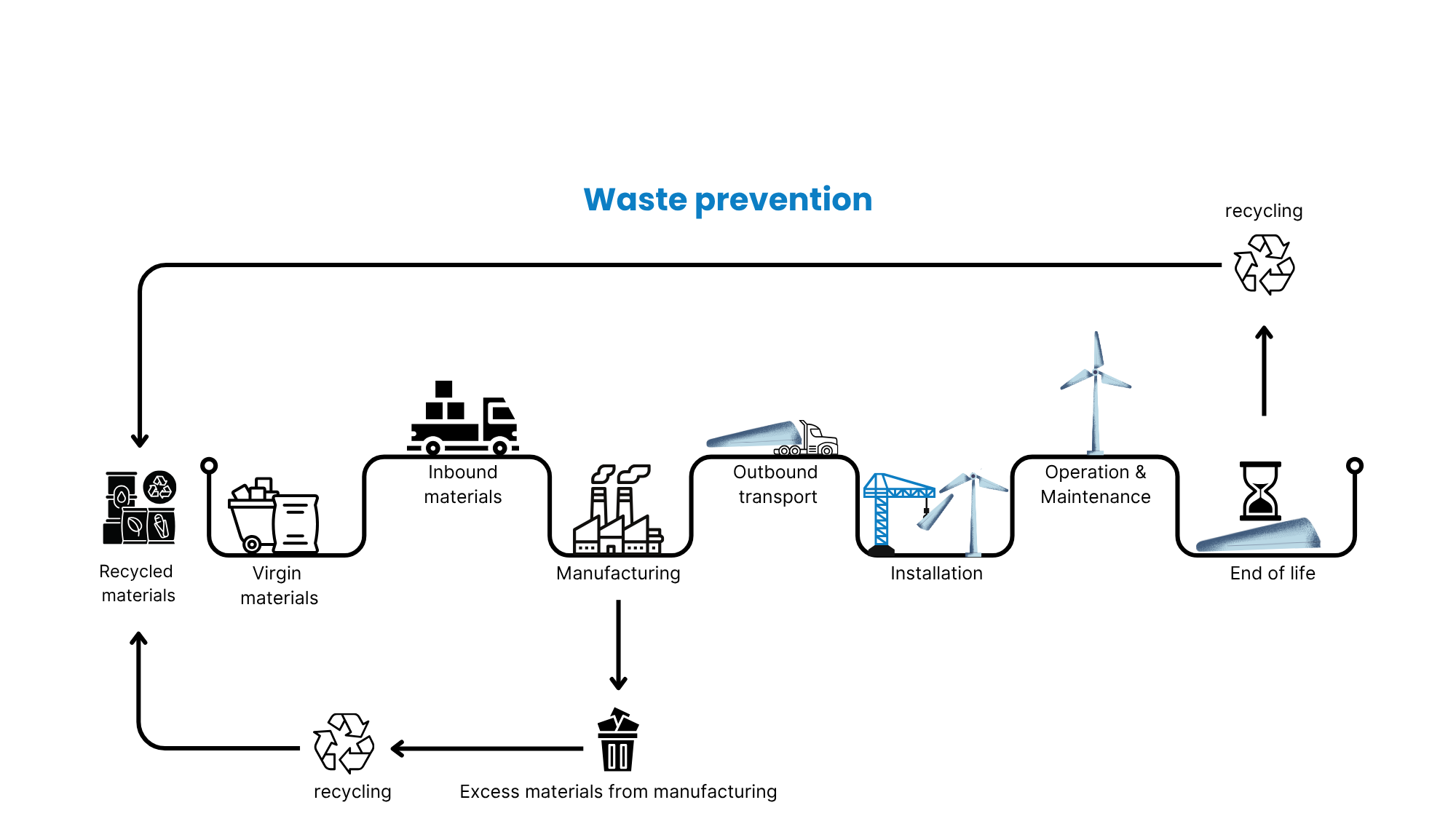

Waste prevention is about eliminating waste from production rather than having to deal with waste once it has emerged. This reduces costs and the environmental and social impacts from waste management.

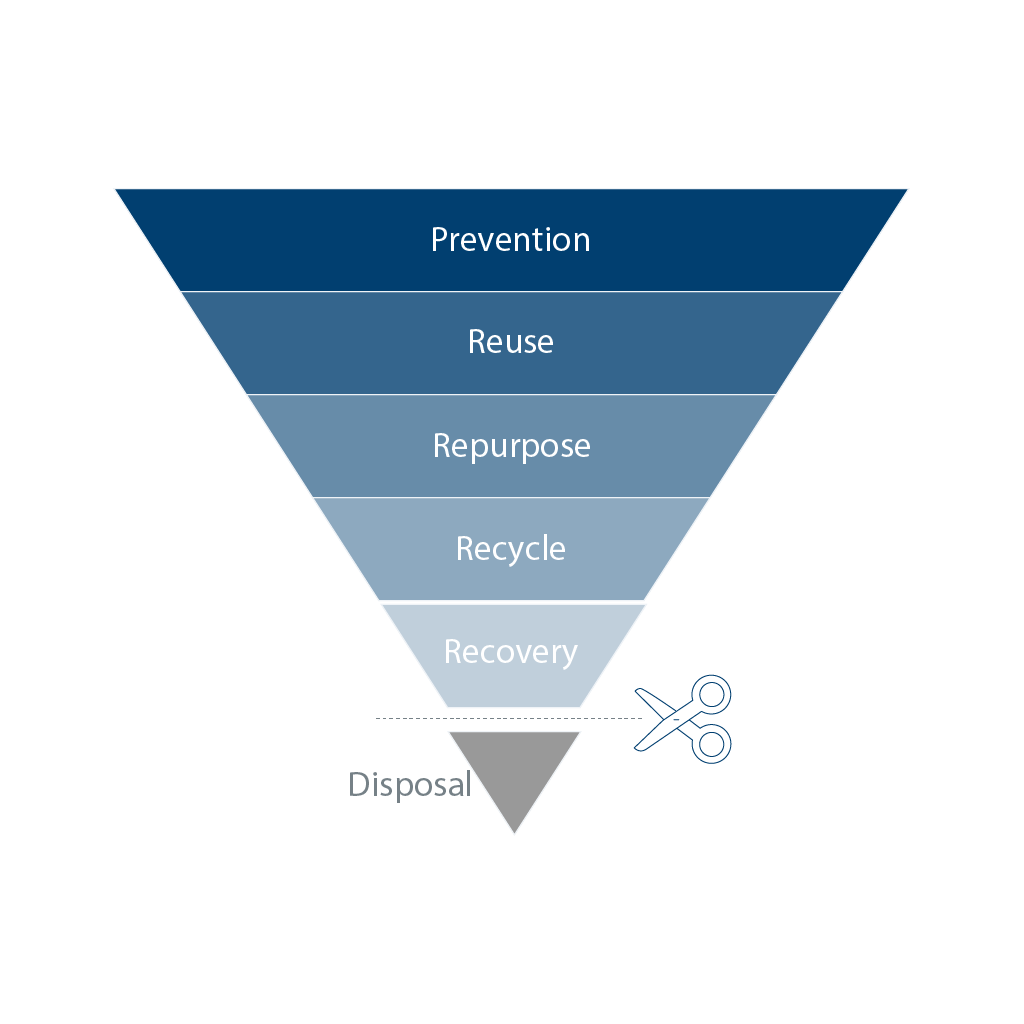

Prevention is the highest level on the waste hierarchy, topping preparation for reuse, recycling, other recovery and disposal. It is focused on reducing or avoiding the creation of waste by, for example, proactively designing wastes out of manufacturing processes.

-Dr. Anne Velenturf (Associate Professor in Circular Economy; University of Leeds)

Circular strategy

Zero Waste Blade focus on preventing, reusing, repurposing, recycling, recovering all the waste from our manufacturing plants and ultimately developing a circular economy for all excess materials from our blade manufacturing.

Environmental Impact

Zero Waste Blade reduces the in-flow and out-flow of materials and thus reduces the greenhouse gase emissions in the blade life-cycle, as well as preserving resources.

Societal impact

Zero Waste Blade facilitates creation of green jobs, creates awareness, encourages sustainable waste management across the whole value chain and the wider society.

Business impact

Zero Waste Blade reduces materials needs and hence cost of material procurement, supports compliance with sustainability directives, enhances brand reputation and drives long-term business value.

Partner

LM Wind Power, an industry-leading developer and manufacturer of wind turbine blades, has produced over 275,000 blades since 1978. LM Wind Power became the first carbon neutral company in the wind industry in 2018 and is committed to building Zero Waste Blades by 2030.

Waste is an opportunity for us

Producing manufacturing waste is inevitable. In the wind industry, around 20-25% of the materials purchased by wind turbine blade manufacturers do not go into the final product. Research indicates that blade manufacturing waste volumes are expected to be larger than decommissioned blade volumes in the coming decade.

But what if we did not waste our waste? What if we took waste that is normally viewed as trash or rubbish and turned it into something valuable to help power a cleaner planet and future for us all?

Reaching zero waste means developing a circular economy for all excess materials from manufacturing, cutting off the tip of the waste treatment hierarchy pyramid.

We embedded our Zero Waste Blades 2030 target as a strategic breakthrough within the company strategy. This program has enabled significant progress toward our 2030 goals.

Preventing waste

A Zero Waste Blades program has been established aiming at reducing direct consumption of materials, which are used in the blade building process. These materials either become a part of the final product (blades) or are discarded as manufacturing waste and are sent to landfill, incineration or recycling.

Putting the spotlight on waste provided focus to our teams and partners to work together in this joint vision. We collaborate with our suppliers by responsibly sourcing materials to lower potential waste, so that we can provide our customers with green products.

An example is the development of an algoritm enabling supply of glass rolls at optimal roll length for each blade design instead of standard length bringing down glass reinforcement waste by 12% providing both enviromental and economic benefits.

The prevention of waste across all our manufacturing plants has improved significantly and the percentage of materials ending as waste of all materials consumed by our production is down from 25% in 2022 to 20% in 2023.

Reuse, Repurpose and Recycle waste

Through training and multiple Kaizen events across our plants key improvement areas have been identified followed by targeted process improvements, and further engaging with suppliers to reduce overconsumption. Further reuse and/or repurposing of consumables (process) materials have also been identified reducing the use of consumables.

Waste recycling often requires partnership. An example of such partnership comes from our plant in India. This involved pyrolysis of the fiber reinforced plastic (FRP) waste under controlled temperature and pressure without any fossil fuel consumption. The pyrolysis oil obtained during the process is used in manufacturing facilities as fuel, replacing fossil fuels/petroleum products. An other example of waste recycling is the used of FRP and glass fiber waste for construction purposes. The picture shows a 3000m long road constructed using FRP waste inside our Dabaspet plant.

Infographic

The challenge continues

While we are working with partners to enable recycling of our manufacturing waste the possibility of recycling waste depends highly on the options available close to our manufacturing sites. In 2023 we managed to maintain the disposal of our waste by recycling at 43%. For many of our manufacturing plants the disposal of waste by incineration is not an option and most of the waste will be disposed to landfill. As an example, because of a change in legislation, the facility where one of LM Wind Power’s operational sites used to incinerate its waste has been closed resulting in a significant increase in disposal by landfilling. For the first time in many years the disposal by landfilling was higher than incineration in 2023. The prevention of waste across all our manufacturing plants has improved significantly and the percentage of materials ending as waste of all materials consumed by our production is down from 25% in 2022 to 20% in 2023.

LM Wind Power

LM Wind Power, a GE Vernova business, is an industry-leading developer and manufacturer of high-quality rotor blades for onshore and offshore wind turbines with blade services solutions and a global manufacturing footprint, headquartered in Denmark. LM Wind Power has produced over 270,000 blades since 1978, corresponding to 152 GW installed capacity. As part of the Company’s sustainability journey, LM Wind Power became the first carbon neutral company in the wind industry in 2018 and is committed to building Zero Waste Blades by 2030.

Other circular strategies

See here the other Circular Strategies, which already provide a frontrunning showcase or are still available for new industry partners!

Repurpose

Repurpose Refurbish

Refurbish Waste prevention

Waste prevention Reuse

Reuse Dematerialise

Dematerialise Remine

Remine